Size detection is the essential link in the process of all products quality inspection, especially in the production process, it is hard to avoid generating deformation and cause a poor quality. With the improvement of manufacturing level, there are lots of class A surface in airplane, appliance, auto parts. The requirement of curve part accuracy is higher. Because of the complex curved surface parts, the traditional detect tool have the questions such as difficult to handle, low accuracy and long detect time.

Meanwhile, materials are widely used by modern manufacturing industry, and some material are easy to deformation. So that those contact measurement testing can’t be done. At this time, the 3d scanner is the best test device.

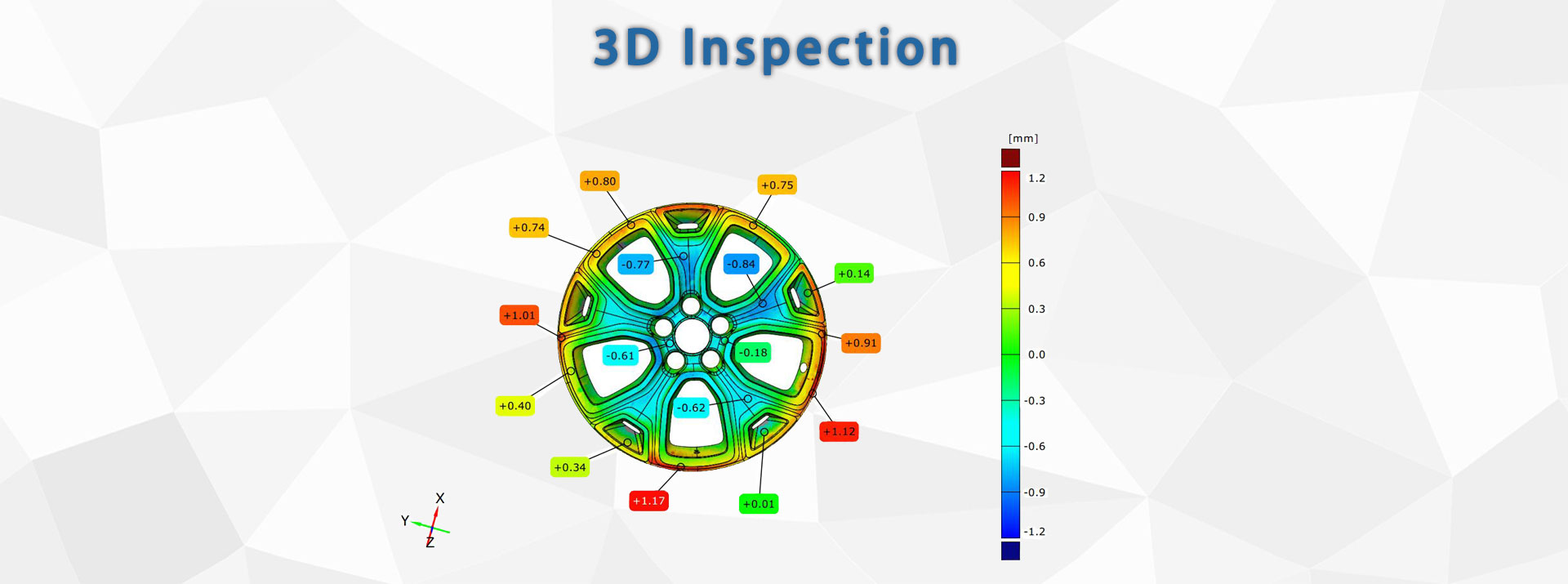

HSCAN 3d scanner plays an important role in the size detection. The 3d scanner obtain the 3d point cloud data and corporate with professional detect software to do the 3d detect, form a CAV full size test report. To do the analysis of point, line and surface. Decrease the detect cost, and promotion the company’s competitiveness.

【ASK QUESTION】